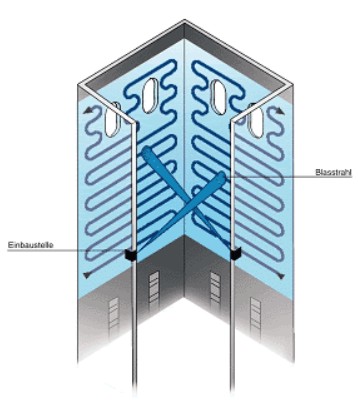

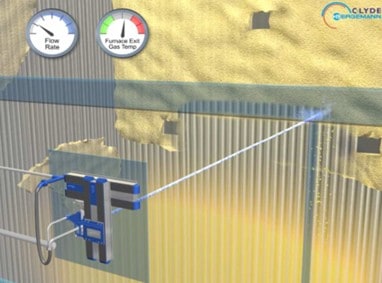

The SMART Cannon represents the most advanced furnace cleaning technology available. Due to its specially developed control technology and precise positioning linear drive, the water jet creates a meander shaped pattern on the side and opposite wall, thereby ensuring timely and targeted cleaning.

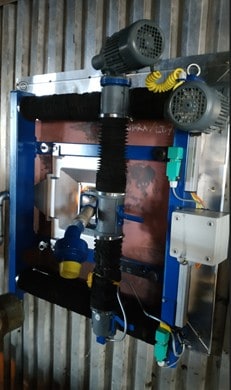

BECAP was awarded with the EPC Contract in Year 2020 to supply and install SMART Cannon in Boiler Unit 7&8 as part of Coal Switch Program. Each Boiler is equipped with 6 SMART Cannon, SMART Controls PLC, CEOS SMART Controls, VFD Pump Skid and 24 units of Heat Flux Sensors installed across the Furnace Wall. The EPC Project was completed in less than 2 years for 2 Boilers, and the SMART Cannon has been in operational since year 2020/2021.

The SMART Cannon is proven to give benefit of Water Wall Cleanliness Index, as well as minimizing and controlling lower Flue Gas Temperature Exit Economizer to APH and Downstream.

Project Background

PT Paiton Energy (Company) operates two identical 615-MW net coal-fired units (Units 7 and 8) that currently fire Indonesian subbituminous coals. In 2022, the boilers will be required to switch coals due to the unavailability of the design coals. The new coals will likely have higher ash content than the original design coals and similar ash fusion temperatures to the existing coals. The boilers have slagging issues and the measures implemented and planned in the near future to address these issues are described below. Additional solutions are sought for the current operations and for an upcoming fuel change. Paiton Energy and its operating entity Paiton Operations and Maintenance Indonesia (POMI) are seeking solutions from qualified contractors to engineer, procure and install water cannon to improve operating availability with the existing coals and with the upcoming change in coals.